Processus de conception personnalisé

Notre processus de conception personnalisée en 6 étapes

Découverte → Prototype → Conformité → Pilote → Production de masse → Support

| Étape 1 : Découverte et analyse approfondie des exigences | |

| Activités: • Consultations techniques détaillées (tension, spécifications environnementales, besoins de conformité) • Analyse de faisabilité des matériaux et des composants • Alignement du budget et du calendrier Livrables : • Document formel de portée du projet (approuvé par les deux équipes) Pourquoi c'est important : • Évite les changements coûteux en milieu de projet en verrouillant les spécifications dès le début. |

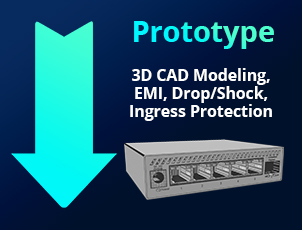

| Étape 2 : Prototypage et preuve de concept | |

| Activités: • Modélisation CAO 3D et simulations thermiques • Assemblage de prototypes fonctionnels • Tests en laboratoire (EMI, chute/choc, protection contre les infiltrations) Livrables : • Prototype fonctionnel + rapports de test • Commentaires sur la conception pour la fabrication (DFM) Pourquoi c'est important : • Identifie les défauts avant l’investissement dans l’outillage. |

| Étape 3 : Conformité et certification | |

| Activités: • Tests de pré-certification (FCC/CE/UL/etc.) • Essais de stress environnemental (température, humidité, vibrations) Livrables : • Feuille de route de certification (avec délais estimés) Pourquoi c'est important : • Empêche les retards dus aux manquements de conformité de dernière minute. |

| Étape 4 : Production pilote et validation | |

| Activités: • Assemblage en petites séries (50 à 100 unités) • Tests sur le terrain en conditions réelles (sites partenaires ou environnements contrôlés) • Affinement basé sur les retours d'expérience (échanges de composants, ajustements du firmware) Livrables : • Unités pilotes pour la validation client + rapports de performance • Nomenclature finalisée (BOM) Pourquoi c'est important : • Détecte les problèmes d'évolutivité (par exemple, les problèmes de taux de rendement) avant la montée en puissance complète. • Valide la chaîne d’approvisionnement : pas de pénurie de composants de dernière minute. |

| Étape 5 : Production de masse et évolutivité | |

| Activités: • Finalisation de l'outillage (moules, gabarits, montages de test automatisés) • Mise en place d'une production allégée (points de contrôle qualité à chaque étape) • Coordination logistique (centres d'inventaire, options de livraison juste-à-temps) Livrables : • Premier cycle de production avec documentation complète (guides d'assemblage, journaux de contrôle qualité) • Feuille de route d'évolutivité (par exemple, capacité à passer de 1 000 à 50 000 unités/mois) Pourquoi c'est important : • Cela prouve que nous pouvons évoluer sans baisse de qualité, ce qui est essentiel pour les acheteurs d’entreprise. • Offre de la flexibilité (par exemple, prise en charge de la production régionalisée). |

| Étape 6 : Assistance à vie et amélioration continue | |

| Activités: • Gestion de l'obsolescence (suivi du cycle de vie des composants, alertes de refonte) • Analyse des défaillances et correction des causes profondes (intégration du processus RMA) • Mises à jour du micrologiciel/logiciel (correctifs de sécurité, mises à niveau des fonctionnalités) Livrables : • Garantie de support produit de plus de 5 ans (extensible) • Notifications de fin de vie (EOL) 12 mois ou plus à l'avance Pourquoi c'est important : • Réduit le coût total de possession (TCO) à long terme : aucun coût de remplacement surprise. • Renforce les partenariats : les clients reviennent pour les conceptions Gen 2. |

Contrairement aux OEM transactionnels, nous traitons votre projet comme une collaboration à long terme, et non comme une commande unique.

Prêt à démarrer votre projet OEM personnalisé ?

Obtenez votre audit de conception gratuit : [ ventes@benchu-group.com ]

Vous souhaitez une estimation rapide pour votre projet OEM ?

Discutez avec un ingénieur maintenant : [ Skype : harry1598 ]